Read our case study with Renishaw

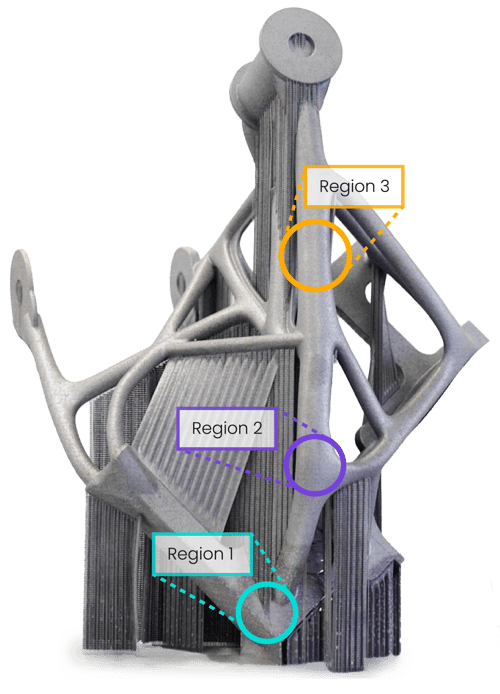

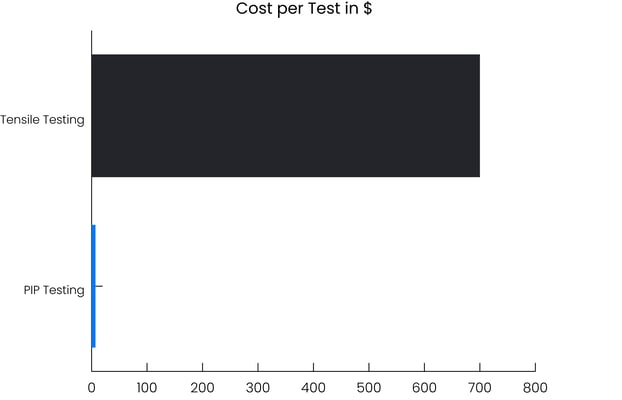

In this case study with Renishaw, we uncover how the varying temperatures throughout a furnace have a significant impact on the mechanical properties of AM parts, in this case showing over 10% variation in yield strength, and how these findings have led Renishaw to optimise their heat treatment process, ensuring consistency and increasing confidence in part performance.