Baked to Perfection: Renishaw’s Insights Into AM Heat Treatment Sensitivity Using PIP

CASE STUDY IN COLLABORATION WITH

Challenge

Heat treatment is a common step in the additive manufacturing (AM) process, used by engineers to control the performance and properties of additively manufactured parts. It’s often a crucial part of turning these intricate designs into strong, usable components that can stand up to the demands of its intended operating environment. We rely on this process to make sure that part properties are optimised for their application, ensuring high performance and longevity in

service.

Intro

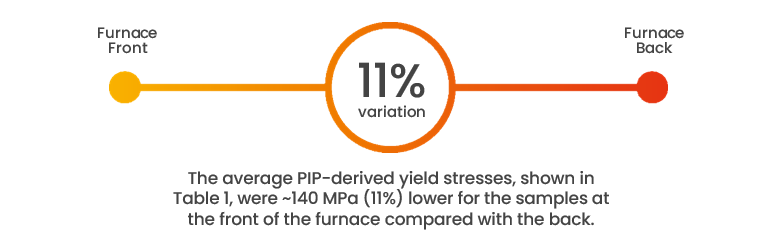

But what if this process, designed to enhance and strengthen, could in fact leave us open to local property variations? In this case study with Renishaw, we uncover how the varying temperatures throughout a furnace have a significant impact on the mechanical properties of AM parts, in this case showing over 10% variation in yield strength, and how these findings have led Renishaw to optimise their heat treatment process, ensuring consistency and increasing confidence in part performance.

Objectives

This case study aims to highlight the variation in mechanical properties across a set of builds which can arise during heat treatments of AM parts and how these variations can be characterised quickly and effectively.

AM materials are commonly heat treated to optimise the properties of the parts and maximise their performance. However, nonuniform heating and cooling conditions within a furnace, due to variable gas flows and heater positioning, can generate unknown variations in heating conditions and resulting mechanical properties. This can increase part-to-part variation or result in differential properties across a large build. Furnace temperature variation can be mapped using thermocouple arrays; however, this does not capture the temperature across the whole build or any direct information about the resulting effect on the material properties.

Another option for verifying and characterising this variation in heat treatment conditions could be to tensile test a large number of witness coupons from across the

Challenge

Unknown variations in heating conditions and resulting mechanical properties can increase part-to- part variation or result in differential properties across a large build.

part (although there is no guarantee that a witness coupon will have experienced a uniform heat treatment across the entire gauge length). Again, this option is not just time, but also material and cost intensive. Hardness testing could generate mechanical data on a finer scale, however these tests generate far less information than a full stress strain curve does.

This case study will show how valuable insight into the inhomogeneity associated with rapid cooling heat treatment, can be obtained using Profilometry-based Indentation Plastometry (PIP) due to the technique’s fine spatial resolution, allowing for accurate mapping of variations in mechanical properties, whilst accelerating testing times and reducing the substantial material requirements associated with pulling witness coupons.

To use tensile testing to characterise variation in heat treatment conditions would require high volumes of material and time, without a guarantee of a tensile coupon having experienced a uniform heat treatment across the entire gauge length.

PIP testing allows for accurate mapping of variations in mechanical properties, whilst accelerating testing times and reducing material requirements substantially.

Materials

Two Inconel 718 builds, each consisting of 16 tensile coupons were built by Renishaw for this work, using laser powder bed fusion. The tensile coupons were all printed vertically, such that the probed tensile direction was parallel to the build direction. Both builds were then heat treated by Renishaw, together in the same vacuum furnace, using their standard Inconel 718 heat treatment.

A 1 bar argon gas quench was used after the solutioning and ageing stages, with the gas inlet positioned at the front of the furnace.

Materials

16 of the 32 coupons were positioned at the back of the furnace, ~280 mm from the argon inlet, whilst the other 16 were positioned at the front of the furnace, as close as 15 mm from the argon inlet (Figure 1). Having been heat treated, the coupons were tested in uniaxial tension and PIP tests were subsequently carried out on the threaded tensile ends. This allowed any variability in the mechanical properties to be characterised through both the tensile and PIP results.

Figure 1: Diagram of a vacuum furnace with 16 coupons placed near the back, about 280 mm from the argon inlet, and 16 coupons positioned about 15 mm from the argon inlet at the front of the furnace.

Measurements

The mechanical properties of the Inconel 718 samples were determined using conventional tensile testing and PIP testing.

PIP is an indentation-based technique which can rapidly derive the stress-strain curve of metallic materials. An indent, approximately 1 mm in diameter and 150 μm in depth, is generated using a spherical indenter tip and the residual indent shape is then characterised using a contacting stylus profilometer. Using the indent shape and an integrated inverse finite element simulation method, accurate stress-strain curves can be inferred from the indent. The test process is fully automated using a PLX-Benchtop device and the full test takes only around 5 minutes to complete.

The PIP tests were carried out directly on the threaded tensile ends such that the indentation direction was parallel to the build direction. A basic surface preparation to a mirror finish was applied to the indented surfaces prior to PIP testing.

PLX-Benchtop by Plastometrex.

Results

The trends identified from the PIP results provided significant insight for Renishaw about the sensitivity of mechanical properties on the variable temperatures generated within the same heat treatment run.

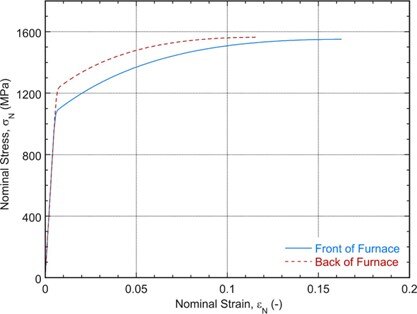

The PIP-derived stress-strain curves for the samples at the front and back of the furnace, shown in Figure 2,

Results

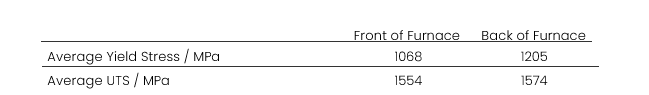

were compared to unlock this insight. The position within the furnace had minimal effect on the measured UTS values, but a more significant effect on the yield stress: the average PIP-derived yield stresses, shown in Table 1, were ~140 MPa (11%) lower for the samples at the front of the furnace compared with the back.

Figure 2: Representative PIP-derived nominal stress-strain curves from each heat treated Inconel 718 build, situated either at the front or back of the furnace at Renishaw.

Table 1: Averaged PIP-derived yield stress and UTS values, for Inconel 718 heat treated at the front and back of the furnace at Renishaw.

Results

The tensile stress-strain curves also exhibited similar trends, with a reduction in yield stress for samples at the front of the furnace and insignificant differences between measured ultimate tensile strengths, whilst also showing good agreement with the PIP-derived results.

However, identifying this trend using PIP is a much faster process, with no significant machining requirements. In fact,

Results

PIP can be carried out on a printed and heat-treated part with only a small amount of preparation. This allows the effects of the heat treatment across a part to be mapped at a far finer resolution compared with tensile testing using a separate coupon, providing invaluable insight into the efficacy of heat treatments across a large or complex part. Through PIP testing, this understanding can be achieved with significantly less demand on time and printed material.

Outcomes

Where gas quenching is used, the location of a part inside the heat treatment furnace can significantly affect its mechanical properties, including its yield strength. Our findings show that parts placed at the front of the furnace (closer to the argon inlet) have an 11% lower yield stress compared with those at the back. This study has enabled Renishaw to identify variation in gas flow conditions when

multiple builds are in the furnace, allowing for the implementation of heat treatment best practices to ensure consistency across builds.

Through this discovery and the use of PIP testing, Renishaw is now able to get a fuller picture of the integrity of parts post-heat treatment than hardness testing alone can provide, without incurring the time and cost penalties associated with tensile testing. For Renishaw printing and testing this Inconel 718 material, the cost for a PIP test is around half that of a conventional tensile test and a quarter of the sample preparation time. PIP derived results equip Renishaw with valuable insights for enhancing heat treatment process developments and understanding their impact. PIP also offers a means to gather actionable information about mechanical properties quickly and easily without needing large

Outcomes

volumes of material. At Renishaw, the findings presented in this case study were used to inform the decision to limit the number of builds or built parts from being simultaneously heat treated in the same furnace, preventing any variation in mechanical properties from being introduced due to furnace position.

Performing PIP studies on small witness coupons also offers potential benefits during production and could be used as a fast and inexpensive way to validate part performance with high spatial resolution. Using PIP as part of a quality assurance process can demonstrate compliance with minimum performance thresholds, measure property variation and provide confidence in results to internal stakeholders, customers and regulatory bodies.

This study has enabled Renishaw to identify variation in gas flow conditions when multiple builds are in the furnace, allowing for the implementation of heat treatment best practices to ensure consistency across builds.

Conclusion

This case study, in collaboration with Renishaw, has been able to demonstrate the value PIP can deliver in rapidly identifying heat treatment associated property variation for a significantly reduced cost compared with traditional tensile testing. Renishaw were able to identify inconsistent conditions during heat treatment and exposed how the position within the furnace resulted in significant variations in mechanical properties. This variable cooling during heat treatment of AM samples can

Outcomes

result in significant variation in part properties. Whilst uniaxial testing of witness coupons can provide some insight to furnace conditions and the effect on mechanical properties, PIP is faster and less costly, as well as offering an advantage in providing finer scale resolution for mapping properties over builds. This provides Renishaw with a competitive advantage in characterising their AM parts, as well as requiring significantly less material for testing, saving time and cost for printing.

UPCOMING WEBINAR

How Renishaw is Enhancing Additive Manufacturing Heat Treatment Processes

When: 25 July, 2 PM BST

Hosted by: Marcus Gaiser-Porter (Materials Scientist, Plastometrex), Jed Robinson-Wall (Materials Scientist, Renishaw), Ben Haigh (Materials Scientist, Renishaw)

This webinar covers:

- The hidden risk: How variations in furnace temperature can lead to significant differences in part properties, with yield strength variations exceeding 11%.

- A faster, more efficient solution: We'll introduce PIP, the testing solution that helped Renishaw uncover the property variations in a fraction of the time and cost required for tensile testing. PIP also operates at a much finer scale than tensile testing, which provided valuable insights into variations across the entire build.

- Real-world improvements: See how Renishaw implemented practical changes, like limiting simultaneous prints in the furnace, leading to more consistent mechanical properties and reduced scrap rates.

- Future outlook: Get a glimpse into other innovative projects using PIP and hear Renishaw’s expert insights on the future of process improvements in additive manufacturing.

Click the button below to sign up.

Meet the PLX-Benchtop

The PLX-Benchtop is a mechanical testing device that extracts metal stress-strain curves from indentation test data.

With users reporting up to 99% cost and time savings compared to conventional tensile testing, parameter development for AM has never been easier.

Get in touch!