Protect Your Pipeline and Your Bottom Line

Click the buttons below to learn more about the PLX-Portable or talk to our team today.

When a pipeline segment reports uncertain material properties, operators are left with two choices: shut it down and investigate, or carry on and risk a catastrophic failure. For a major North American pipeline operator, the decision was clear, but costly. After a conservative yield strength reading from a material verification tool cast doubt on the integrity of one of their pipeline joints, operations paused, crews mobilised, and pipe was physically removed for destructive testing.

The result? The material was in fact compliant. The reading was wrong. The bill? Over $800,000.

This was not a failure of the pipe, it was a failure of the data. Worse, this incident is not an outlier. As integrity management professionals across North America scramble to comply with the PHMSA “Mega Rule” and similar regulations, inaccurate material verification is emerging as one of the most expensive and dangerous blind spots in pipeline integrity management. In a regulatory environment where accurate grade identification is mandatory, bad data isn’t just inconvenient, it’s a major liability.

Material verification has become an essential part of modern pipeline integrity management, particularly in the wake of regulations like the PHMSA Mega Rule, which demands more robust records and more accurate knowledge of pipe material properties (or Grade), especially in high consequence areas. But the rise of in-situ, non-destructive material verification tools now begs the question - just how reliable are the data they produce?

In a recent round-robin study of material verification tools on seamless pipes, the PLX-Portable from Plastometrex delivered a mean absolute percentage error of just 3.6% on yield stress. In contrast, the next most accurate tool came in at 9.1%, and the worst-performing tool recorded a significant 16.8% error. One commonly used system has even been shown to miss the mark by as much as 35% when estimating yield strength (as shown in a 2018 PRCI report). These aren’t just marginal differences - they highlight potentially catastrophic risks when low-accuracy tools are used for critical decisions.

The most dangerous outcome from a material verification test is an unknown overestimation of the yield strength. This can lead to an overestimation of the Grade and, therefore, an overestimation of the Maximum Allowable Operating Pressure (MAOP). For example, if a pipe’s actual yield strength is 52 ksi, but a tool reads 70 ksi (i.e. a 35% overestimate, for consistency with the reported maximum overestimate of the common tool mentioned earlier), then the operator might calculate MAOP based on an erroneous material grade, resulting in a pipe being operated above its actual safe pressure limit. That’s a serious risk to human life, the environment, and public trust.

Conversely, while underestimation of material strength may at first glance seem benign, it has serious financial consequences. When a pipeline is deemed weaker than it truly is, operators face tough decisions:

Imagine, for example, a pipeline segment rated for 1,000 psi, but an underestimated reading from a sub-standard material verification tool raises concerns about the pipe’s true capacity. For some operators, derating might seem like the safe option, but in practice, a decision that significant often requires validation through destructive testing, particularly when the measurement feels unexpectedly low.

That kind of testing doesn’t come cheap. Recall the North American operator mentioned earlier that was faced with a site shutdown and an $800,000 bill to sense-check a conservative material verification result which, in the end, was proven wrong.

If operators did choose to proceed with derating, say, dropping from 1,000 psi to 750 psi – that’s a 25% reduction in throughput. For a transmission pipeline moving millions of cubic feet per day, such a downgrade can translate into millions in lost revenue over time, not to mention grid-wide inefficiencies in pressure balancing and contractual delivery performance.

Over a 10-year horizon, the cumulative cost of an unnecessary derating decision could stretch into the tens of millions, depending on pipe length, diameter, and flow volume, all because of a poor-quality reading that couldn’t be trusted.

With so much riding on their readings, the question for integrity management engineers has now shifted: It’s no longer about whether a tool can measure, but how accurately it can do so under real-world conditions.

We’ve already explored the significant delta in MAPE between the most accurate tool, the runner up and other alternatives, as cited by the recent PRCI round robin, but what does this then mean for grade identification?

Whereas most tools offer a single-point estimate of yield strength and tensile strength, more in-depth methods for grade identification have emerged. Consider the Grade Estimation Method integrated into the PLX-Portable. Here, the tool’s industry-leading yield and tensile strength measurements are integrated into a Bayesian-based Grade Estimation Method. The PLX software suite evaluates the measured yield and tensile strengths against known distribution curves for pipeline grades (per API 1176) and provides probabilistic outputs to support grade estimation.

This probabilistic approach to grade estimation represents a significant step forward from traditional single-point methods, offering operators a clearer, more confident view of their options. But even the most sophisticated models depend entirely on the quality of the data they’re fed. In recent independent benchmarking, including the 2024 PRCI round robin, the PLX-Portable was identified as the most accurate tool currently available. When paired with this advanced estimation method, that level of precision can mean the difference between confidently identifying a single grade, or being left with multiple possibilities and no clear answer. And when operational decisions hinge on that answer, feeding poor data into even the best model can be as risky as having no data at all.

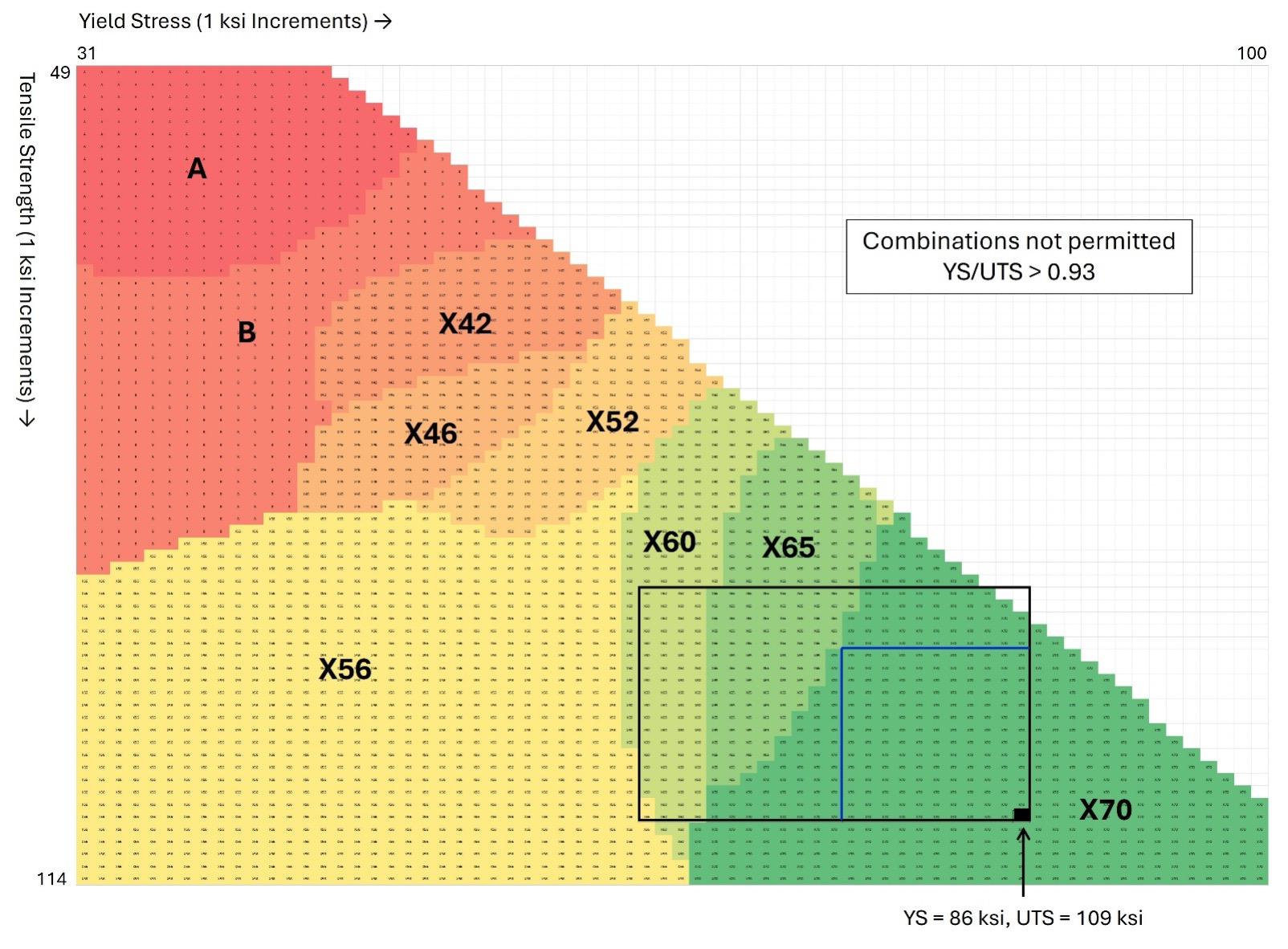

Below in Fig. 1, the sensitivity of these grade estimates to large values of maximum overprediction are highlighted in a colour-coded contour map of combinations of yield strength versus tensile strength:

This simple analysis indicates that the tool with a maximum overprediction of 35% leads to 4 possible candidates for grade, while the PLX-Portable leads to 1 candidate (at least when the yield and tensile strength are measured at 86 ksi and 109 ksi, respectively).

Fig.1: A colour-coded contour map of yield stress versus tensile strength, with increments of 1 ksi. The colours show the grade that is predicted by the Plastometrex Grade Estimation Method for all combinations of yield and tensile strength. The thick black box represents the range of possible combinations that are permitted by the other common tool for a measured combination of yield stress = 86 ksi and tensile strength = 109 ksi with a maximum overprediction of 35%. The thick blue box shows the corresponding bounding box for the PLX-Portable from Plastometrex.

The PHMSA Mega Rule and similar regulations have shifted the burden squarely onto operators: know your pipe. Reconfirm your MAOP. Validate unknown segments. And if you don’t have traceable, verifiable, and complete (TVC) records, then you must verify material properties using approved, reliable methods. Otherwise, inaccurate tools can silently drive multi-million-dollar losses or catastrophic overpressures. For operators, integrity engineers, and safety managers facing tough choices under tough regulations, the case is clear:

Click the buttons below to learn more about the PLX-Portable or talk to our team today.