Fast & Reliable Pipeline Material Verification

Boasting industry-leading accuracy, the PLX-Portable delivers reliable stress-strain results quickly, non-destructively, and in-situ, with report-ready pipeline material verification data available immediately from the dig site.

PLX-Portable

Employing the proven scientific methodology - PIP - the PLX-Portable provides non-destructive and reliable material verification data, straight out of the ditch and available immediately from anywhere via our cloud-based platform, PLXUS.

Industry-leading accuracy

The PLX-Portable has set a new industry standard, with record MAPE values for yield and tensile strength.

Reliable data

Simple, guided operation, automated testing and system safeguards keeps you free from risk of technician error and data uncertainties.

Streamlined & scalable testing

Simplified surface preparation, followed by a 30-minute per quadrant test, delivers quick results, with 2-day training to get your teams up and running fast.

Final results in the ditch

Results are generated straight from the dig site, with report-ready data available immediately and accessible from anywhere via cloud-based platform.

Our partners

Globally leading provider of cutting-edge solutions in all areas of asset integrity

Leading provider of testing, inspection and certification services

National measurement standards laboratory for the UK

UK Government Award

How it works

- Grind surface using hand-held, off-the-shelf tools.

- Attach cradle to pipe using our bespoke strap-tightening system.

- Connect the indenter module and perform an indent.

- Our software - CORSICA - then analyses the profile shape and gives a full stress-strain curve and real-time strength data. The whole process takes under 30 minutes and requires only one person to operate.

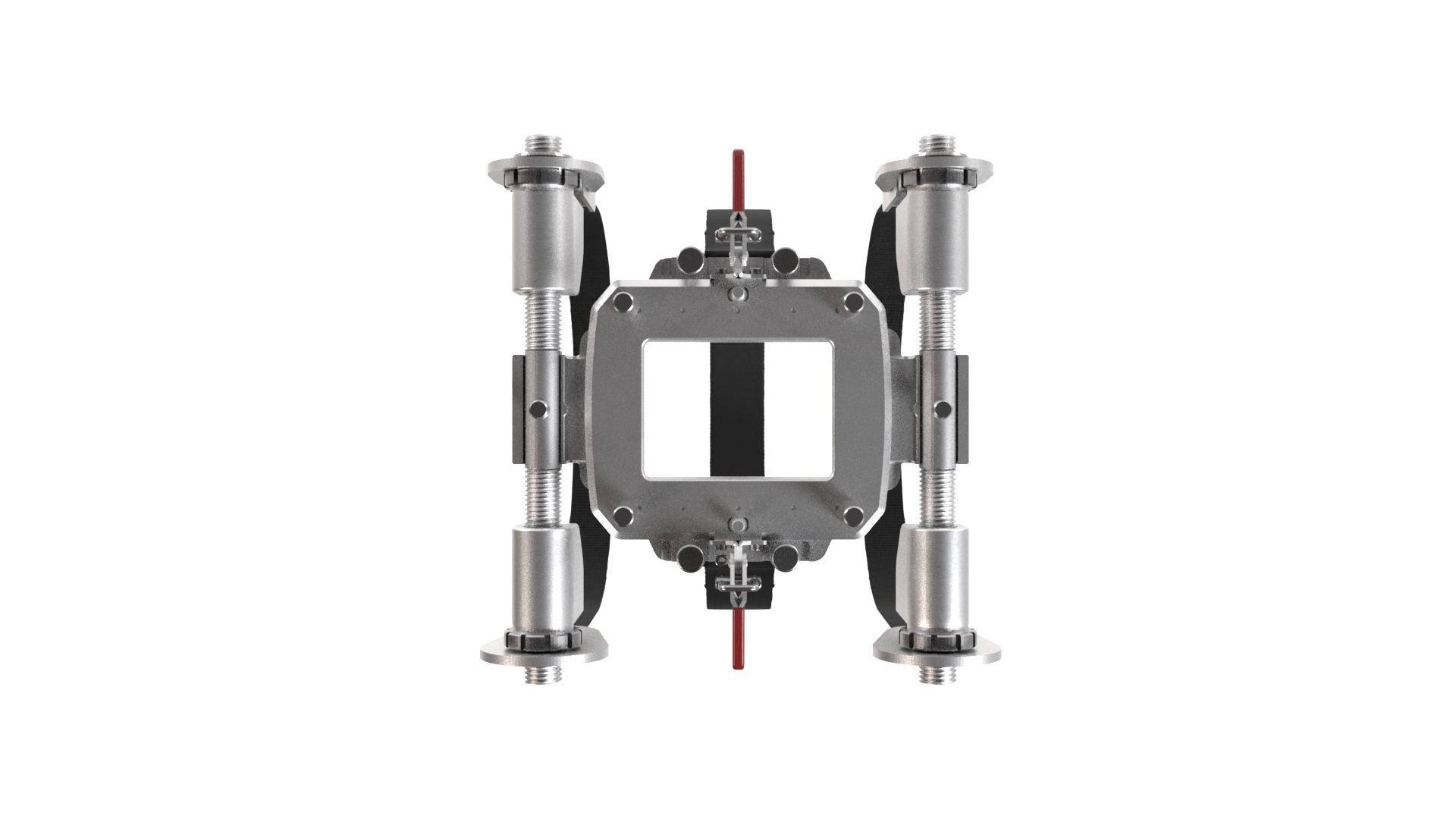

Included kit

Cradle and supporting accessories

Indenter

module

Optical profilometer

module

Setting the standard for accuracy

MAPE (Mean Absolute Percentage Error) is a common assessment method for material verification systems in the pipeline industry, where a lower value indicates better performance.

The PLX-Portable consistently achieves the lowest MAPE value in the industry, most recently of 3.6% for yield and tensile strength, as well as lowest maximum error, as cited in a key industry report.

The cost of inaccuracy

Tune into our upcoming webinar where CTO, Dr Jimmy Campbell, uncovers how common material verification technologies can misjudge pipe strength by up to 25%, and shares solutions to protect pipeline integrity.

Register now for The Cost of Inaccuracy: How to Achieve Material Verification Reliability

“The PLX-Portable tool enables us to provide fast and reliable material verification, which will result in safe, compliant pipelines and facilities over their lifetime.”

Joel Troyer, Vice President of Industrial Solutions

Learn more

Want to learn more about the PLX-Portable? Complete the quick form below and we'll be in touch!